You asked, and we listened. We at OKdo are passionate about technology and innovation, so we gathered all our forces to make a single board computer that we, and YOU, always wanted – the ROCK, and bring to the table everything you’ve been asking for, as standard. We believe that tech is the key to driving positive and innovative change. Together, as a community of fellow tech professionals, we can build an exciting future and empower amazing things through technology.

Richard Curtin, the co-founder and CTO of OKdo, shares everything you need to know about ROCK, and how we can customise and tailor it to your needs, allowing you to build the future you want and drive SBC design innovations.

Let’s meet the new single-board computer, solid as a ROCK!

So, what is ROCK? It’s a range of reliable and low-power single-board computers developed in collaboration between OKdo and Radxa. It offers class-leading capabilities, hardware and performance in a similar form factor as other popular SBC boards.

ROCK series are versatile boards formed with high-performing hardware, as standard. What’s more, the ROCK boards can be fully customised and configured just the way you want it because it’s your board, in your way. This brings huge financial and environmental benefits during current supply chain challenges, allowing professional design engineers to leverage cutting-edge technology for developing high-volume end products.

It offers professionals, industrial OEMs, IoT enthusiasts, hobbyists, PC DIY enthusiasts and makers a reliable and capable platform for bringing their ideas and projects to life, supporting the most extraordinary next-generation technology applications.

Why ROCK?

OKdo ROCK was born out of our love for technology. Having listened to what you really needed in a single board computer, we decided to build something different. We wanted to create a better board, to allow people to build a better future for the world. Here at OKdo, we are committed to offering you the best hardware and software to maximise the potential of your design applications.

We aim to build a community of engineers passionate about tech & electronics, who want to be part of something different, be part of a community that will drive change and be BETA together. We believe in the power of ROCK, and we also believe our community can help make it even better.

If you get a kick out of creating, innovating, hacking and being part of bringing an awesome new product to market, then we’d love to hear from you.

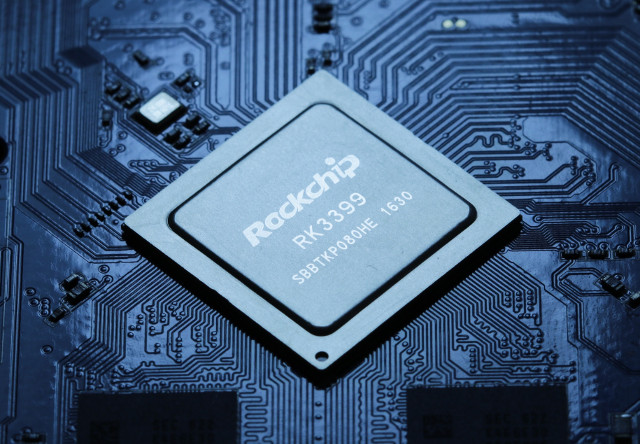

Rockchip – a powerful processor at the heart of ROCK

The ROCK boards are designed around processors provided by Rockchip, a fabless semiconductor company based in China. Although Rockchip have sales of billions of dollars in China or the APAC region, they have a very modest market share position in Europe and North America. Nevertheless, they’ve gained an outstanding reputation outside of Asia and continue to grow and expand globally.

What’s great about using the publicly available processors from Rockchip is that they offer detailed product information, such as comprehensive datasheets. If you are a professional user and you’d like to internalize the technology, the bill of materials (BOM) used by Rockchip is openly available in the market.

One of the greatest advantages of Rockchip is the diversified model they use to produce their wafers in fabs. Considering the supply chain constraints that Taiwan Semiconductors have had lately, there is a significant risk of stock shortages when the production of semiconductors is solely located in Asia or in one wafer fab.

Rockchip, on the other hand, use several different fabs to produce their wafers, meaning that they have been able to ride the supply chain storm better than some other semiconductor companies. This was one of the main attraction points when we initiated the design, manufacture and distribution partnership with Radxa, a Rockchip design partner, to solve our customers’ problems.

ROCK products are designed by a talented engineering team from Radxa in China. They’ve approached their engineering by considering how they can provide everybody, from education and makers to industrial customers, with scalable, robust platforms using next-generation technology. It has been another key differentiator that laid the foundation of our partnership with Radxa and Rockchip.

We are also expanding our semiconductor design strategy with some of the largest semiconductor suppliers in the world.

What ROCK products is OKdo bringing to the market?

Nowadays, customers who have been designing using single-board computers have been impacted by severe supply chain constraints that caused projects to stagnate. To help resolve the SBC availability issue, we’re excited to partner with Radxa and bring to market a robust roadmap of ROCK products.

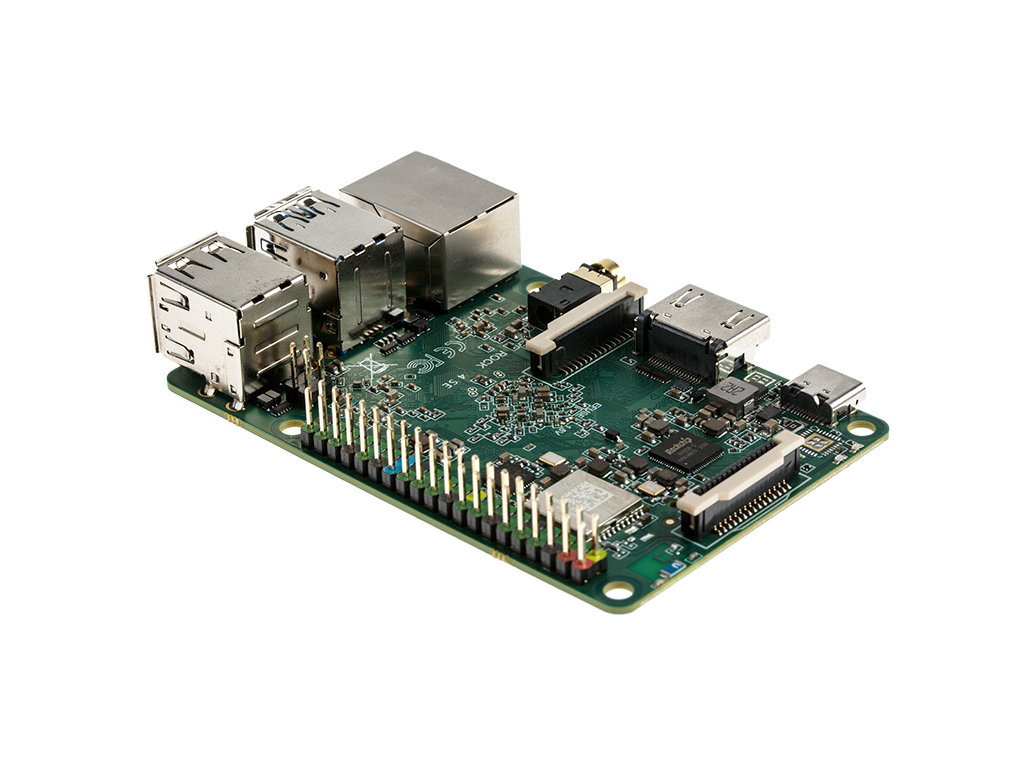

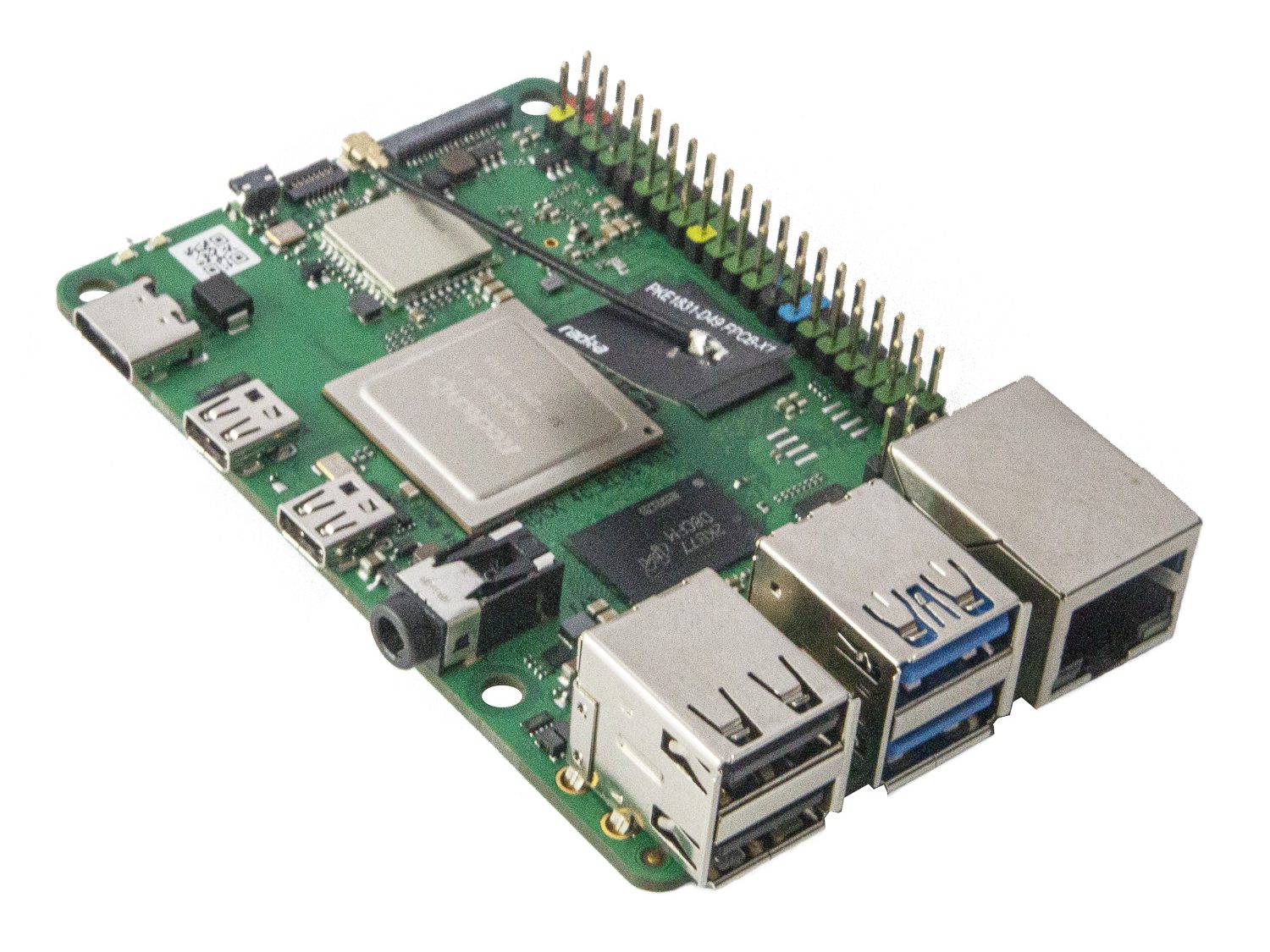

At first, we introduced the special edition board, the ROCK 4 SE, and the ROCK 4C+, which meet most of the design and cost requirements previously satisfied by other SBC brands. But now, the next generation of SBCs, the advanced, resilient & multifunctional board, the ROCK 5B, is finally here.

Packed with incredible features, including its powerful Rockchip RK3588 SoC, the ROCK 5B is the first SBC supporting 8K displays, tailor-made for advanced multimedia applications.

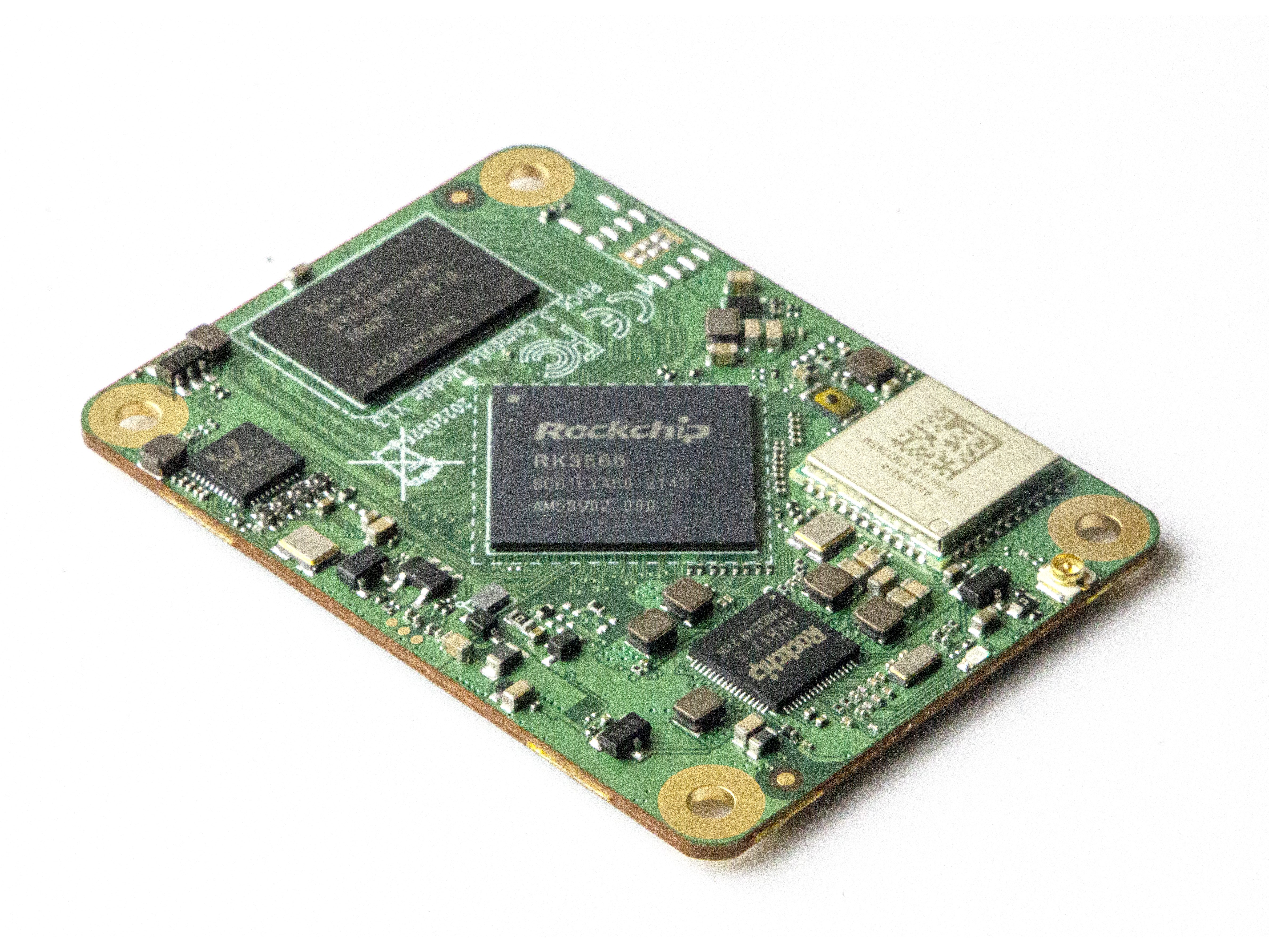

Depending on your design needs, there is a board that will ROCK your project. Whether it’s the next-gen ROCK 5B SBC, or the ROCK 3A, or a ROCK CM3 Compute module, be sure you can trust that your board will be as solid as a ROCK.

Discover the ROCK Shop

Why is ROCK the perfect single-board computer for your next design application?

- Designed with world-class hardware, providing advanced functionality and performance.

- Developed to benefit from a wide range of existing accessories available on the market, assisting developers to discover new products during this time of constrained supply while also pushing the limits of what’s possible.

- Supported by a System on Module (SoM) & carrier board strategy. Compute modules (also called SoMs) have industry-leading expansion options beyond anything else in the market today while still retaining backwards compatibility with existing OEM products that have hit production stops due to chip shortages. And carrier boards enable developers to quickly make use of the never seen before features.

Whereas not a single product can solve every single problem, we at OKdo will continue to build the broadest SBC range in the world to be able to offer each and every customer what they need to be successful.

How can we help you?

OKdo is very flexible! We can do anything from implementing full-scale design changes to the boards - customisation, to the other side of the spectrum, which is linked to our sustainability agenda where we offer customers the opportunity to remove components from the SBC while maintaining the integrity of the layout, a process we call configuration.

But we’re also ensuring that the board is compliant and the costs are transparent. What’s more, we can still offer amazing logistics and distribution services to our customers anywhere in the world.

Here at OKdo, we offer:

- Off-the-self boards,

- Customisation and configuration services,

- Design services

- A range of System-on-Module (SoM) platforms – meeting design customer needs, solving their problems, reducing costs and improving time to market.

How to customise your boards with OKdo?

Customisation can be as simple or as complex as the customer desires. Once the customer has contacted us, providing us with some basic information that will allow us to understand what problem they would like to solve and what they’d like to achieve, a salesperson and a technical engineer will follow up to discuss the request in detail. Then, the customisation process begins.

Services beyond product

Richard Curtin shares the excitement about introducing solutions that will facilitate the design and development of next-generation technology

I feel immensely proud of the journey that we’ve been on, and it is incredibly exciting. When we established OKdo, it was always my aspiration to ensure that OKdo was a company that offered services beyond product. We had a mission to build the world’s best line card and availability of single board computers for our makers and education customers, but we also wanted to ensure we could offer product solutions to meet the needs of our global industrial, professional design customers.

But I also knew that was never going to be enough. If we just offer products off the shelf and distribute them, we would be doing the same as many companies around the world. The aspiration in the strategy for OKdo was to build intuitive ways for us to offer services that would solve customer problems.

When I think about where we are today in the world with these incredibly challenging supply chain dynamics with design cycles rapidly evolving, I feel that we couldn’t have chosen a better time for OKdo to launch customisation and manufacturing services backed by the RS Group’s amazing logistics and distribution.

I think it really puts us in a very enviable position. But most importantly, it puts us in a position where we can genuinely help customers, and the introduction of the ROCK platforms in this part of our journey is just incredible.

Who would imagine that we’ve now got a next-generation technology available with a really robust supply chain, with an amazing service wrapper that is unrivalled in the industry? I think that as we move forward, this will be something that engineers, designers, and developers will be interested in learning more about and taking advantage of. So, it’s an incredibly exciting step forward for the OKdo team and our strategy.

What news and exciting launches are coming next to OKdo?

As you can imagine, just like the world of technology, it never stands still, and we at OKdo are already thinking about the next steps.

Later this year, we will announce the launch of the latest ROCK platform, a next-generation technology. There isn’t anything like it in the market right now. It will offer more scope to our engineering customers from a technology and design perspective.

In parallel with that, we’re developing a new software journey. I’m very excited to say that later this year, OKdo will also be making available several major embedded design software packages that will continue to help our customers with their design journey.

Keep an eye on our ROCK Shop to discover more exciting products that will be coming into our range and be the first to know about the latest boards, compute modules and accessories coming into the ROCK shop, ready to bring your ideas to life.

ROCK Shop

Let’s invent the future together

Here at OKdo, we aim to help you solve your problem and support you with identifying the right solution that will work for you! Your board, your way. Have it the way you need it!