Every project has its own incredible purpose and unique requirements. One way to solve the everlasting riddle when choosing the most suitable hardware and software to optimise production costs and efficiency is customisation. With OKdo ROCK, you can design your own single board computer, add or remove components, and ROCK your next project with the ideal custom SBC with your own choice of hardware and software. Because it’s your board, in your way.

Our range of multifunctional, robust & high-performing ROCK single board computers and compute modules allows us to customise the board and adapt it to your design requirements. With a team of passionate and highly-qualified engineers, we aim to work together with you and find the best solution to help you boost your project.

We’ve interviewed Richard Curtin, the co-founder and CTO of OKdo, who talked about all you need to know to design your own single board computer with OKdo, and ROCK your next projects with custom SBCs, specially tailored to suit your design needs.

Read along to find out what SBC customisation is, how a custom ROCK single board computer can help you, what elements can be customised, and how you can greatly benefit from it.

Q: How customising your single board computer can boost your project?

R: Historically, engineers and designers used development boards/evaluation boards to evaluate the silicon before integrating them into their bespoke design, the performance of the microprocessor, its power consumption, and how it interacts with other software stacks. But this has changed quite dramatically in the last ten years.

Now, single-board computers are increasingly becoming an integral part of end applications due to their form factor, cost, excellent connectivity, I/O interfaces, and the most up-to-date processing power.

Aggregating the compute and I/O elements to a single product manufactured by us represents a massive resource-saving when it comes to these times of supply constraints. By aggregating the volumes, we, together with our global manufacturing partners, can leverage the combined power of the SBC users vs. single smaller customers who only source for their individual boards.

Here at OKdo, being able to offer our design customers a customisation service is really important to us. We know that engineers using SBCs and modules as part of their final design face several obstacles they need to overcome, and we are ready to help them solve these problems.

For example, customisation allows engineers to change how SBCs connect to their end applications, change the form factor of the SBC to better meet the need of those end applications, remove or add functionality that will enhance their design performance and ultimately, the end product. Therefore, customisation is so important for us, and we’re pleased to offer it to our customers.

Customisation with OKdo starts with the problem that the customer is trying to solve – either the platform that they’ve got right now doesn’t quite meet their needs, or they need to make fundamental changes. Still, they see customisation as a path of least resistance because the circuit and the platform already work. So, if they can make some adjustments to that and add it into their final design, that might overcome problems linked to design delays, supply chain and cost, both financially and ESG (Environmental, Social and Governance).

Q: Who can benefit from OKdo’s customisation service?

R: We will customise a board based on the volume demand. Unfortunately, today OKdo can’t customise a board for home use, for a maker, like myself, or somebody who is doing a project on a small scale. However, we’re constantly watching the market and listening to our customers’ needs, therefore in future, we may consider building derivative boards to satisfy the growing demand.

We’re focussing on bringing the customisation service to industrial professional design engineers, who have an application that is produced on a large scale of thousands of units. This makes customisation much more viable.

Q: What elements of an SBC can be customised?

R: The advantage of customisation is that it’s flexible, and the single-board computer can be tailored to a customer’s specific requirements.

For example, a customer may use ROCK 4C+ but doesn’t need the Ethernet connector. Removing the Ethernet connector from the board will only slightly reduce the cost over 500 units, but it will help the customer to solve the problem of space or efficiency.

Some connectors (Ethernet being one of them) imply other hidden costs too. The controller chip can also be removed along with its clocks and supporting components. Then just imagine how heavy 500 metal Ethernet RJ45 plugs weigh and the loss supported in terms of baggage charge on a plane or the CO2 footprint of shipping if the excess is not going to be used for the intended application.

Q: How can you bypass customisation?

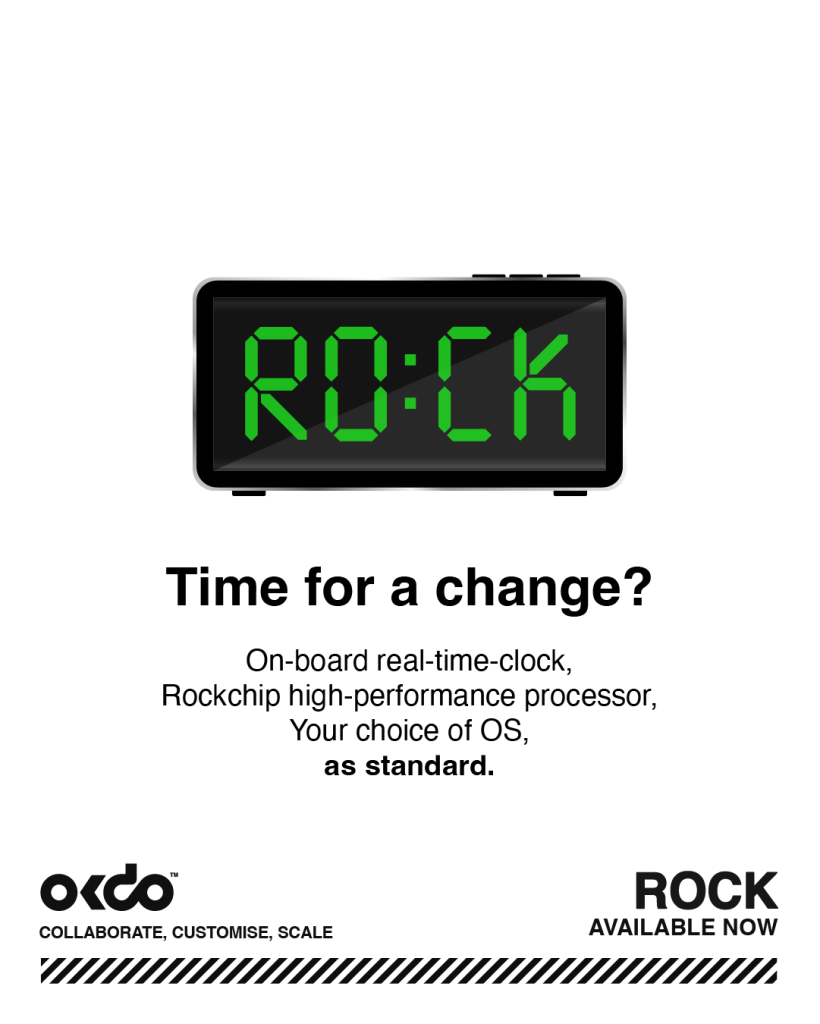

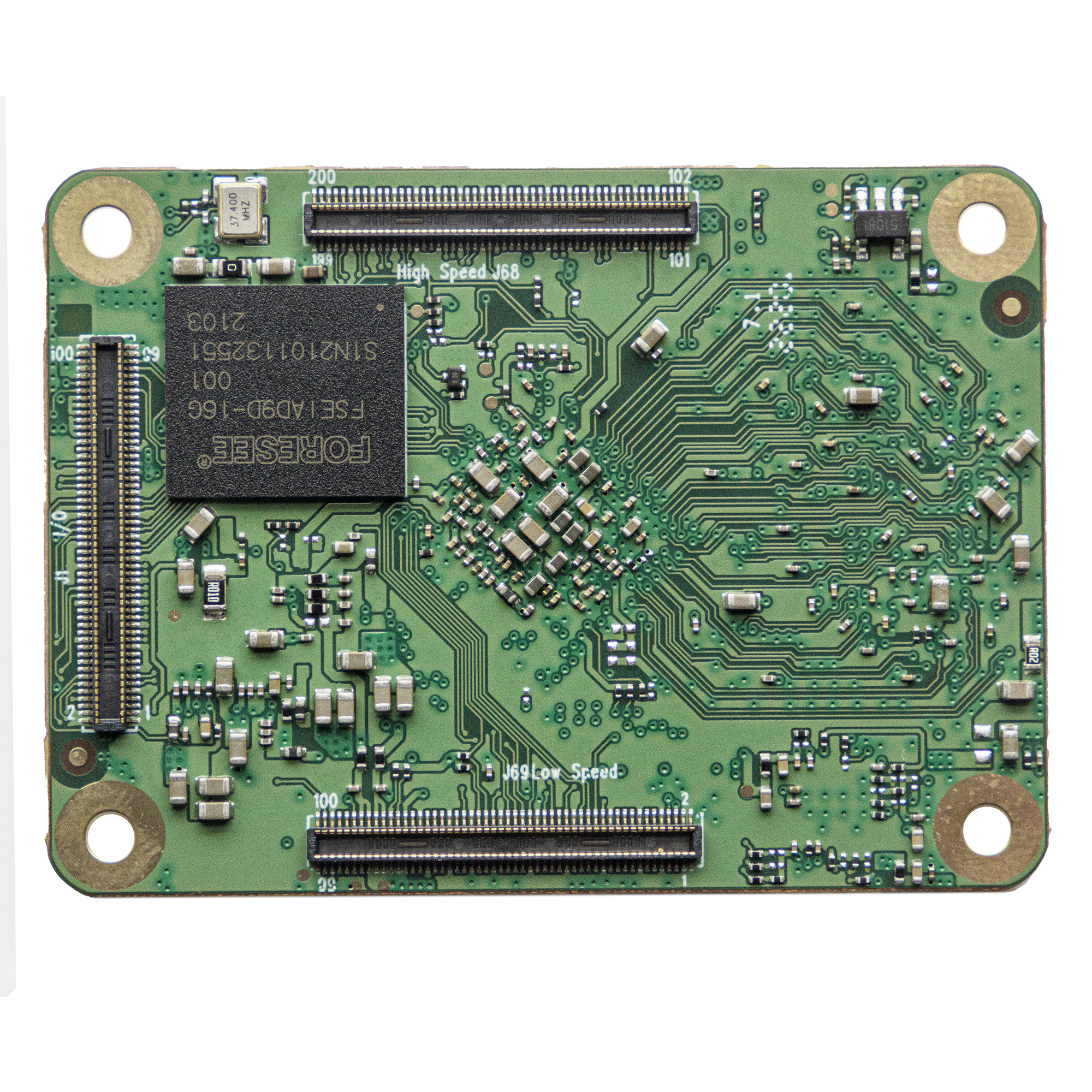

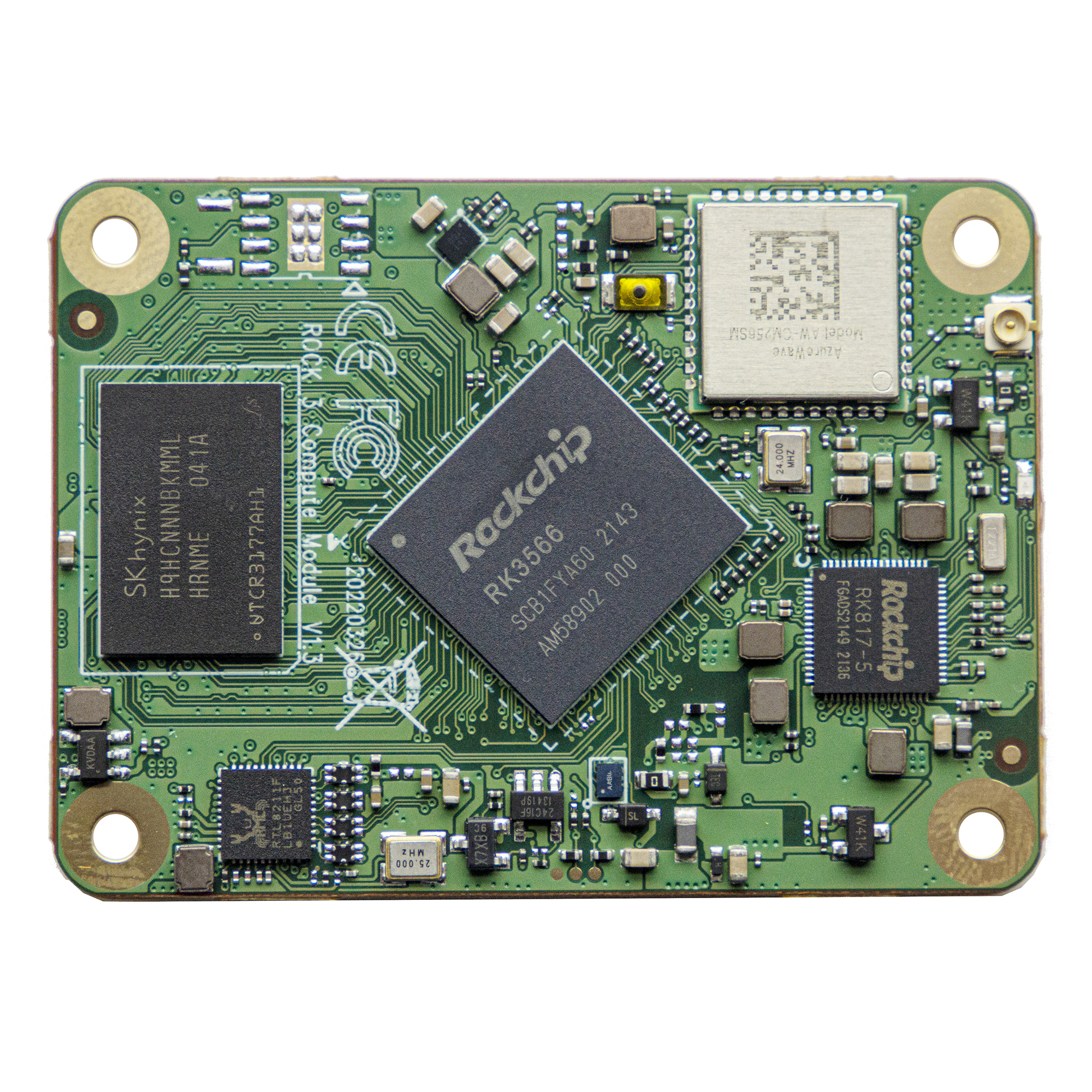

Customers may be able to satisfy their design needs with off-the-shelf single board computers, such as the ROCK 4 SE, ROCK 4C+, and the ROCK 5B. However, the customer can sometimes bypass the customisation journey using a compute module, what we also call a SoM. We at OKdo can then help them with the distribution, the logistics and the supply chain to meet specific requirements.

ROCK compute modules – the perfect solution to bypass customisation.

Our global application engineering team will be able to advise if one of the available compute modules would be better suited for the requirements of their end application or would help reduce costs or improve the time to market.

Still, if it doesn’t, and they have more technical requirements around customisation, our customers can visit OKdo’s website, complete an enquiry form and get in touch with our sales and applications engineering team to discuss personalisation in detail.

N.B. What is a SoM? A system on a module (SOM) is a board-level circuit that integrates a system function in a single module. It may integrate digital and analog functions on a single board. A typical application is in the area of embedded systems. Unlike a single-board computer, a SOM serves a special function like a system on a chip (SoC).

Another example is where a customer may not need any of the connecting interfaces on the board, any of the USBs or the Ethernet connector; the only thing they want is the power supply. They might also say they need to increase the board’s memory. For example, ROCK 4C+ is currently available with 4GB RAM, but the customer may need 8GB memory to run dual displays or develop other applications.

Our customisation service allows us to do that for them, but that would be quite a complex design service. To accommodate that, there are a few steps that need to happen.

Firstly, we will test the board again for compliance because we’ve changed it significantly. Secondly, a design service cost would be applied, a cost called non-refundable engineering (NRE). In addition, we would give a price for the new board with the NRE as a separate cost or amortised into the build of each unit.

For example, if a customer needs 5000 boards, and the NRE would be £5000; we might propose adding £1.00 to each board we deliver to amortise the engineering cost into the final board’s cost, which some customers will prefer.

BLOG: WHY ROCK?

ROCK Shop

Q: How does customisation impact production costs and the time to market?

R: It really depends. Here at OKdo, we’re trying to solve a customer’s problem, give them access to the latest technology and the latest content, including product datasheets and offer a solution that is available with a reliable supply chain, reduced cost and reduced time to market. These are some of the most common problems customers face daily in this current market.

OKdo will be working closely with our customers to identify what we can do to ensure that we don’t increase costs unnecessarily, that we don’t increase time to market, and that we’re acting with due diligence. This is the number one priority of OKdo’s design and technical teams.

The 3 main benefits of SBC customisation:

1.

Reduced Costs

2.

Tailored to your requirements

3.

Reduce component waste

The first question is, how can we improve time to market? For instance, our latest SBC ROCK is a readily available platform with a robust supply chain. So, we already tick a box if this is what the customer is looking for. It allows us to work within a timeframe of available stock, which is really powerful.

The second question is, how can we reduce costs? We offer customers the ability to change the boards in whichever way they need to. Still, they might not always be interested in reducing costs but may require stock availability in a very competitive lead time, adding additional functionality to a trusted platform that helps speed up their go-to-market time with their end product.

And the third question is, how can we reduce component waste, as well as the negative environmental impact? SBC customisation allows removing certain components from the board that are not required for the intended application. First of all, this reduces the CO2 footprint of shipping, as well as prevents unused components from ending ap as landfill waste.

Customisation is a balancing act between “what is the problem the customer is trying to solve” and “what is the solution we can offer to meet their needs”.

Q: How to customise your boards with OKdo?

R: Customisation can be as simple or as complex as the customer desires. Once the customer has contacted us, providing us with some basic information that will allow us to understand what problem they would like to solve and what they’d like to achieve, a salesperson and a technical engineer will follow up to discuss the request in detail. Then, the customisation process begins.

Let’s invent the future together

Here at OKdo, we aim to help you solve your problem and support you with identifying the right solution that will work for you! Your board, your way. Have it the way you need it!